-

Lubrication and monitoring system in concrete mixer

For the lubrication of the whole concrete batching plant, domestic or imported oil are ok. For China brand, we recommend CHANGCHENG. For imported oil, we suggest Mobil, ESSO, SHELL. BP, etc. For the concrete mixer, there are 4 points to lubricate. The first three are important. 1. The shaft head sealed grease pump: Mobil NLGI 1 or NLGI 2 grease. 2. Reduction gear: Mobil GEAR629 3. Hydraulic station oil tank: Mobil DTE 25 4. Other lubrication points: hinge in the observation door, cylinder pivot point, jackstay in motor base plate, small grease needed every 2-4 weeks. Observe the oil level and oil quality through oil window: oil level should be in the 1/2-2/3 of the oil window. If oil level is too low, please replenish. If oil quality turns bad, please renew it. Please make sure that the air vent in the oil plug (oil filter point) is unobstructed. Otherwise, the air expansion in the oil tank will cause tank leakage. For both lubrication oil and grease, their viscosity will change as the...

-

concrete mixer starting system and normal operation mode

Since the power of concrete mixer is large, in order to reduce the impact to the power grid, the machine should starting by Y-△(star-delta starting). Besides, it should start with no load and start alternately with the inclined belt. According to the Current number in no-load and full-load, we can confirm if the machine is working well by checking the ampere meter on the manipulate platform. The empirical number of rated current of machine: Amotor power X2. If no-load, the Current is 1/3 A. For example, in HZS180 concrete batching plant, we use SICOMA 3m3. The total power of two driving motor are 110kw, rated Current is 220A. In no-load condition, the Current will be about 70A, and the current should be stable. The normal operating condition: no excessive vibration, no abnormal sound, no oil leakage, no leakage in discharging gate or shaft head. Voltmeter, ampere meter indicates as normal. The highest temperature during running should be less than 80 ℃, the maximum temperature rise...

-

MP Planetary Concrete Mixer

MP Series Planetary Concrete Mixers are manufactured using German technology. This kind of mixer not only applies to produce common commercial concrete and precast concrete but also have solved many problems about High Performance concrete mixing. Planetary concrete mixer is suitable for mixing dry hard concrete (roller compacted concrete)....

-

HZS35 Concrete Batching Plant

Based on the world’s leading technologies, we researched and developed HZS35 ready mix concrete batching plant. It is suitable for the commodity concrete and concrete construction in each kind of architectural project, including the water conservancy, the electric power, the railroad, the road, the tunnel, the arch of bridge, the harbor-wharf and the national defense-project and so on, the applicable scope is extremely wide....

-

10 Layer Building Equipment Diesel Concrete Pump 45kw Without Crane

Diesel concrete pump mixer is suitable for all kinds of dispersed locations, less construction, longer distance from site to commodity concrete agitate plant. For example: 10 layer below the group main building structure, building and underground garage floor, civil construction of inclined roof, small bridges, tunnels, water conservancy slope, small river locks and boat lock, electric power communication tower base, small wharf, mine construction, concrete roadway maintenance field sites scattered, engineering the quantity is less, the commodity concrete batch plant is not willing to do or they do not economic construction, concrete construction project site mixed.Diesel concrete pump mixer is with the rapid and flexible, mobile convenience, speed, labor saving features....

-

HMC450 Self-loading Concrete Mixer

HMC450 Self-loading Concrete Mixer is a mini-mobile concrete batching plant, its capacity Of one Batch is 4.5m3, it owns all the functions of concrete batching plant, loading, weighing, pumping, mixing, travel, discharge and washing. It can produce concrete independently and efficiently in remote areas....

-

Electric Concrete Pump(HBT Series)

Electric concrete pump is a kind of concrete pump adopting electrical engine power source, it mainly used for concrete transportation. It adopts electricity as its original power, unlike the diesel concrete pump, the concrete pump with electric engine only can work in the areas with sufficient electricity power. The electric concrete pump adopts the electric motor, which can provide stead and constant power when it is on work. Compared with the diesel engine concrete pump, the concrete pumps with electric motor is more convenient and used widely....

-

HMC5025 Truck Concrete Pump Boom

25 small concrete pump truck is the refined product among the middle and short arm pump truck, after HBT trailer concrete pump, HBC truck-mounted concrete pump, HGY hydraulic concrete placing boom, and it is the high efficient concrete conveying equipment integrating driving, pumping, placing.The boom covers high reliability, economy, safety, durability, owning reasonable matching of Chassis, power, electric control and hydraulic pump system.Besides, it has flexible telescopic boom, less space occupation of the leg, convenient moving vehicle, flexible and security....

-

HMC350 Self-loading Concrete Mixer

HMC350 Self-loading Concrete Mixer is a mini-mobile concrete batching plant, its capacity Of one Batch is 3.5m3, it owns all the functions of concrete batching plant, loading, weighing, pumping, mixing, travel, discharge and washing. It can produce concrete independently and efficiently in remote areas....

-

YHZS25 Mobile Batching Plant

YHZS25 Mobile concrete mixing plant which adopts advanced technologies and scientific researching results from home and abroad and combines our company’s years’ mixing station producing experience, which is a new type mobile concrete mixing station designed by our company independently .It is now one of the best mixers in China, which boasts compact and reasonable designing. Most functions of the mixing station are finished in the pulling chassis, combining aggregate, electronic weighing, mixing and lifting together.It can be stopped to run or be pulled away easily, which is convenient to move and easy to install....

-

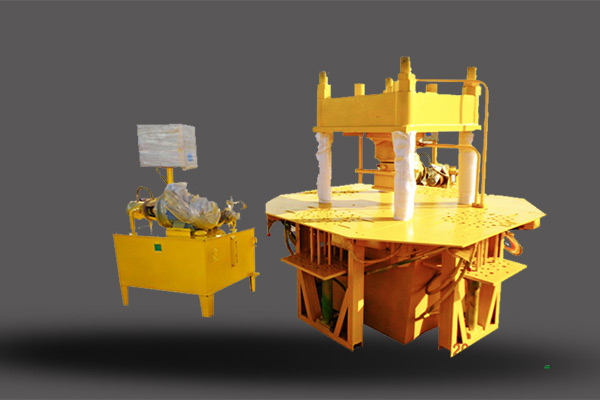

HM-150T Paver Block Making Machine

DY-150T Paver Block Making Machine adopts mass flow automatic variable pump and electromagnetic hydraulic valve, with high pressure, rapid lifting, compression automatic bounce back, and adjustable compressing time, high productivity. can produce many kinds of paver and interlock bricks,just exchanging the moulds.DY-150T Paver Block Making Machine using large-flow automatic variable pump and electromagnetism valve to meet strong pressure speedy lifting and pressuring time adjustment....

Why Choose HAMAC?

Q: Are you a factory or trading company?

HAMAC: We are a company which include trade and industry. We have our own factory which has been manufacturing concrete machineries along with spare parts for 20 years offline.

Q: How about the quality control of your productions?

HAMAC:All of our products passed ISO9001:2000, some of them got CE Certificate. We have a very strict quality control system, all of our suppliers are selected strictly and carefully. We will take strict inspection

before the goods shipped.

Q: What do you think is the most competitive advantages when comparing with other suppliers?

HAMAC: HAMAC only present true information to all of our clients, HAMAC only provide our clients with high quality machines. Most of our clients are regular clients, it is a proof of our quality. And the new buyers

would like to repeat orders from us since we are not only sell goods but also services.

Q: How do you think the relationship between quality and price? Relationship between buyer and seller?

HAMAC:If you care about the quality, please respect its price. If you only care about the price, do not expect a good quality. Market price is well-known, the seller will not quote a higher and unreasonable price

to push away the buyer.

One deal, to make one new friend. Reputation is the most important thing. HAMAC will not destroy the reputation because of an order. We are pursuing long-time cooperation.

Solutions

Concrete Mixer

Self-loading Mobile Concrete Mixer

JS series Concrete Mixer

Self-loading Mobile Concrete Mixer

JZ series Concrete Mixer

JZR Diesel Driven Concrete Mixer

European Tech.Twin shaft Concrete Mixer

MP Planetary Concrete Mixer

Concrete Mixer with Pump

SICOMA Double Shaft Concrete Mixer

Products

Concrete Mixers

Concrete Batching Plant

Concrete Conveying Plant

Related Concrete Equipment

Concrete Block Making Plant

NEWS

- A Successfully Case about MP1000 Was Made with Mexican Customer

- HZS90 Concrete Mixing Plant and Loading Machine Were Shipped to Indonesia

- A set of concrete mixer with pump was delivered to Ecuador

- Concrete mixer with pump delivered to Saudi Arabia

- Two sets of Concrete mixer with pump arrived customer's site

- HBT08 Concrete mixer with pump ready for delivery

- Hot sale concrete placing boom delivered to Dubai

- HZS180 Being Installed in Mongolia

- Mobile Concrete Batching Plant YHZS75 Was Delivered

- Self-loading mobile concrete mixer ready for delivery

Get Quote

Get Quote Chat Online

Chat Online