Automatic Brick Manufacturing Plant

Automatic Brick Manufacturing Plant is a Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

While above all, the most important is, we will keep providing customer the same quality and the same service as we always does and be proud of, so no worry and no hesitate, we are waiting for you, we hope to get your message and inquiry in no time.

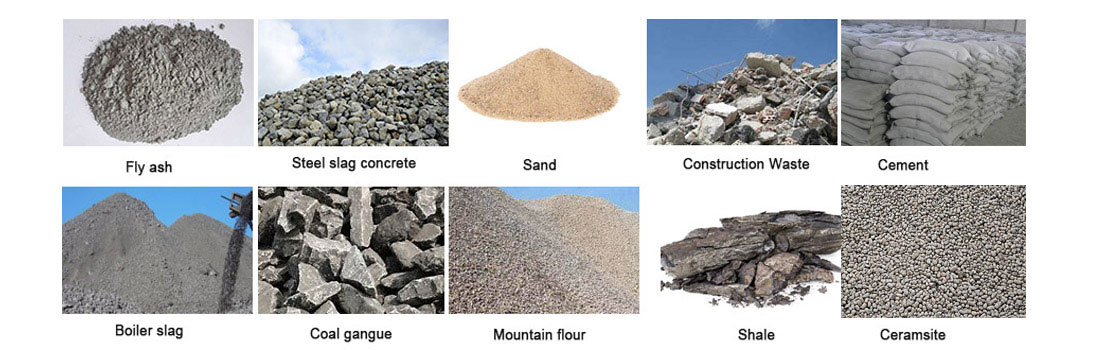

RAW MATERIAL

Brick Production Process

1. Automatic Batching Station

2. Concrete Mixer

3. Cement Silo

4. Screw Conveyor

5. Cement Scale

6. Bucket Conveyor

7. Pallet Conveying System

8. Block Making Machine

9. Face Mix Section

10. Block Conveying System

11. Block Sweeper

12. Automatic Elevator

13. Automatic Lowerator

14. Block Pushing System

15. Pallet Tumbler

16. Finger Car

17. Automatic Cuber

18. Central Control Room

19. Hydraulic Station

20. Exit Conveyor

21. Curing Chamber

22. Wheel Loader

23. Fork Clamp

1. Cement silo and screw conveyor: The cement silo is used to store the bulk cement which is used for concrete. The screw conveyor is connect with the cement silo and concrete mixer to transfer the cement into the concrete mixer. These two parts are optional parts. You can get them at local market or purchase them from us together with our block making machine;

2. Aggregate batching machine: It consists of two or three storage bins and one weighing bin. It also contains belt conveyers which is used to convey aggregate and sand from the storage bins to weighing bin. Batching and weighing is controlled by PLC.

3. Concrete Mixer: All the ingredients are mixed in this concrete mixer. Mixing time and speed is controlled by PLC. The water pump which is controlled by time relay adds water to the mixer automatically;

4. Belt conveyor: after the concrete is ready, it will be discharged to this belt conveyor, the belt conveyor will transfer the concrete to the concrete block machine;

5. Automatic Brick Manufacturing Plant: This is key part of the production line. It presses the concrete to block. It can be used to make various hollow block, solid brick, paver brick and kerbstone by changing different sizes moulds;

6. Stacker: Stacker is used to stack the blocks automatically, which is high-efficient and labor saving.

7. After the above procedures, the blocks will be transported to the storage yard for drying.

Equipment

Automatic Brick Manufacturing Plant is the most advanced, reliable machine for making high quality, high intensity concrete blocks or fly-ash bricks. Multiple producing lines with different configurations can satisfy clients' manufacturing and capacity requirement of most concrete products. HAMAC has expanded its business to South Asia, South America, Eastern Europe and Africa as a trusted supplier of concrete machinery.

QT4-15 Concrete Block Making Plant (Capacity: 9600-15360 Pcs/8 Hr)

QT4-15 Automatic Brick Manufacturing Plant is a Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

This equipment is the most advanced, reliable machine for making high quality, high intensity concrete blocks or fly-ash bricks. Multiple producing lines with different configurations can satisfy clients' manufacturing and capacity requirement of most concrete products.

Tags:automatic soil brick making machine,build your own brick making machine

JS500 concrete mixer is a kind of double shafts forced type mixer, it can be used separately and can be used together with a concrete batching machine to be a simple type concrete batching plant. It is being widely used in various scale of prefabricate concrete parts factory, and much construction of road and bridge, dam, port and so on. It could be used to produce dry concrete, plastic concrete, fluidity concrete, lightweight aggregate and various kinds of mortar.

1. Special drum prolongs the service life of the steel wire rope.

2. Concrete intensity test proves the excellent performance of the mixing equipment.

Tags:earth brick making machine,pavement making machine

QT6-15 Concrete Block Making Plant (Capacity: 14400-23040 Pcs/8 Hr)

QT6-15 Automatic Brick Manufacturing Plant is a Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

This equipment is the most advanced, reliable machine for making high quality, high intensity concrete blocks or fly-ash bricks. Multiple producing lines with different configurations can satisfy clients' manufacturing and capacity requirement of most concrete products.

Tags: cement concrete bricks manufacturing,best brick making machine

JS750 concrete mixer is a kind of double shafts forced type mixer, it can be used separately and can be used together with a concrete batching machine to be a simple type concrete batching plant. It is being widely used in various scale of prefabricate concrete parts factory, and much construction of road and bridge, dam, port and so on. It could be used to produce dry concrete, plastic concrete, fluidity concrete, lightweight aggregate and various kinds of mortar.

1. Special drum prolongs the service life of the steel wire rope.

2. Concrete intensity test proves the excellent performance of the mixing equipment.

Tags:mud brick making machine suppliers,latest brick making machine

QT8-15 & 10-15 Concrete Block Making Plant (Capacity: 14000-37000 Pcs/8 Hr)

QT8-15 Automatic Brick Manufacturing Plant is a Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

This equipment is the most advanced, reliable machine for making high quality, high intensity concrete blocks or fly-ash bricks. Multiple producing lines with different configurations can satisfy clients' manufacturing and capacity requirement of most concrete products.

Tags:diy brick making machine,solid brick making machine

QT10-15 Automatic Brick Manufacturing Plant is a Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

This equipment is the most advanced, reliable machine for making high quality, high intensity concrete blocks or fly-ash bricks. Multiple producing lines with different configurations can satisfy clients' manufacturing and capacity requirement of most concrete products.

Tags:bricks production machine,industrial brick making machine

QT4-20 Concrete Block Making Plant (Capacity: 3200 - 6400Pcs/8 Hr)

QT4-20 Automatic Brick Manufacturing Plant is a Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

This equipment is the most advanced, reliable machine for making high quality, high intensity concrete blocks or fly-ash bricks. Multiple producing lines with different configurations can satisfy clients' manufacturing and capacity requirement of most concrete products.

Tags:brick making machine for sale uk,paving bricks machine for sale

Concrete Pan Mixer is widely used for making paver blocks and bricks. Our Concrete pan mixer is provided with mechanical gearbox. Provided with heavy structural steel, these pan mixers can also be customized in accordance with client requirements. Concrete pan mixer belongs to vertical shaft concrete mixer. It is a type of concrete mixer with fast and homogenous mixing effect due to its special structure design.

1.. High automatic degree, high mixing quality, high efficiency, low energy consumption.

2. It can combine with dosing machine to form a small and medium batching plant

Tags:brick machines for sale,brick molding machine for sale

QT5-20 Concrete Block Making Plant (Capacity: 5000 - 65000 Pcs/10 Hr)

QT

QT5-20 Automatic Brick Manufacturing Plant

cinder block making equipment, Cost of block making machine

PLC control system: set the technical parameters such as flow and pressure of each action through the touch screen to achieve ideal man-machine dialogue. The control system consists of three control units: batch mixing automatic program control system, molding host, transport board machine, lift-unload automatic program control system and weight control system. The electrical components of this system are all imported brand products, such as Mitsubishi, Omron, Siemens, etc, thus ensure reliable performance and low failure rate.

Multi-purpose of one machine: By replacing the mold, it can produce cement products with different specifications of porous bricks, hollow blocks, roadside stones, pavement bricks, grass bricks and slope protection bricks. The fabric device can produce products such as colorful pavers.

Case

-

QT8-15 Automatic Block Making Machine in Russia

Capacity : 14000- 37000 Pcs/8Hr

Equipment :QT8-15 Automatic Brick Manufacturing Plant + JS750 Concrete Mixer + Wheel Loader

More >>

-

QT4-15 Automatic Block Making Machine in Russia

Capacity : 9600- 16350 Pcs/8Hr

Equipment :QT4-15 Automatic Brick Manufacturing Plant + JS500 Concrete Mixer + Wheel Loader

More >>

Get Quote

Get Quote Chat Online

Chat Online